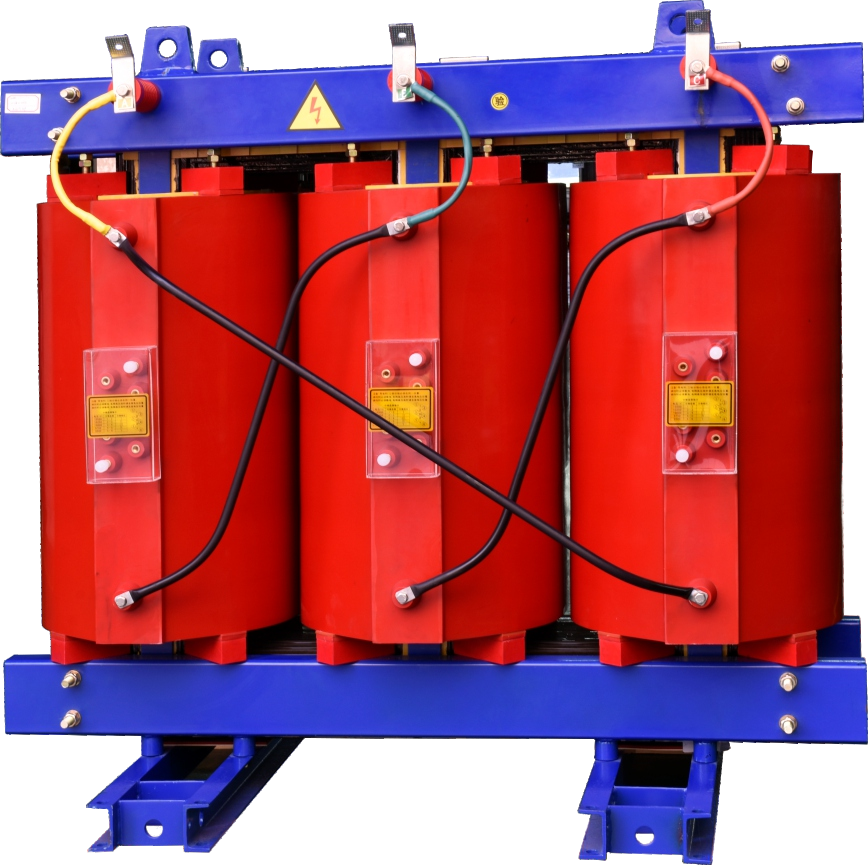

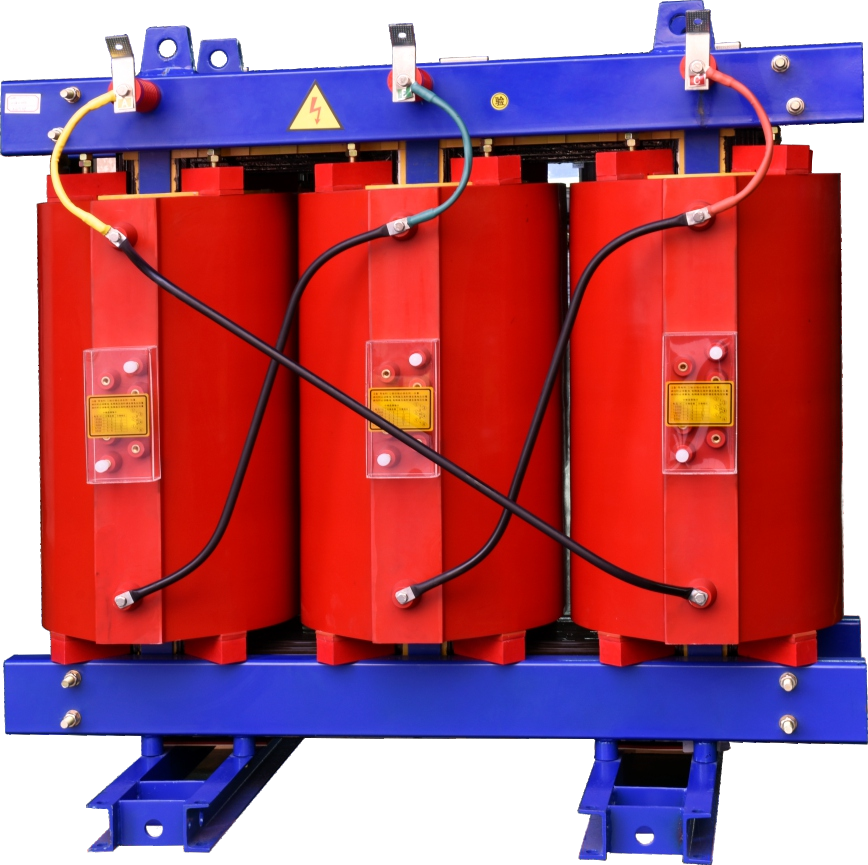

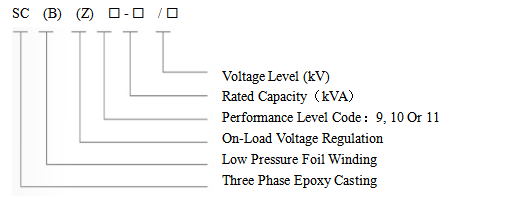

SCB11, 13F Insulated Dry Distribution Transformer

SCB11, 13F Insulated Dry Distribution Transformer uses thin layer epoxy resin pouring to seal the dry Transformer with high- and low-pressure winding. The design is reasonable, the process is advanced, the local discharge power is small, the noise is low, and it has flame retardant, self-extinguishing, moisture-proof, heat dissipation is good, and maintainability., non-polluting and other characteristics. The surface of the iron core and clamp is specially treated with protective resin and has a beautiful appearance. The low-pressure foil is wound, and the high pressure adopts a segmented multi-layer cylindrical structure to make it evenly distributed, with small magnetic leakage, high mechanical strength, and strong short-circuit resistance.

TEL:16515111777

Product details

SCB11, 13F Insulated Dry Distribution Transformer uses thin layer epoxy resin pouring to seal the dry Transformer with high- and low-pressure winding. The design is reasonable, the process is advanced, the local discharge power is small, the noise is low, and it has flame retardant, self-extinguishing, moisture-proof, heat dissipation is good, and maintainability., non-polluting and other characteristics. The surface of the iron core and clamp is specially treated with protective resin and has a beautiful appearance. The low-pressure foil is wound, and the high pressure adopts a segmented multi-layer cylindrical structure to make it evenly distributed, with small magnetic leakage, high mechanical strength, and strong short-circuit resistance.

◆The high-pressure winding adopts lacquer copper wire, and the low-pressure winding uses foil winding. The high-pressure winding is filled with fiberglass felt and poured with unfilled imported epoxy resin in the vacuum state. After curing, it forms a solid whole, with high mechanical strength, no partial discharge, and high reliability.

◆ Fire-retardant, explosion-proof, non-polluting environment, environmentally friendly, can be installed in the load center;

◆The coil does not absorb moisture, and the iron core and clamp can be operated in 100 % relative humidity and other harsh environments after special processing. Intermittent operation does not require desiccation treatment;

◆High anti-short circuit, high level of lightning shock, high overload ability;

◆The inner and outer resin insulation layer of the coil is thin and has good heat dissipation performance. The cooling method generally uses air natural cooling (AN). Air cooling system (AF) can be configured for Transformers of any protection grade;

◆ Small size, light weight, small space, easy to install.