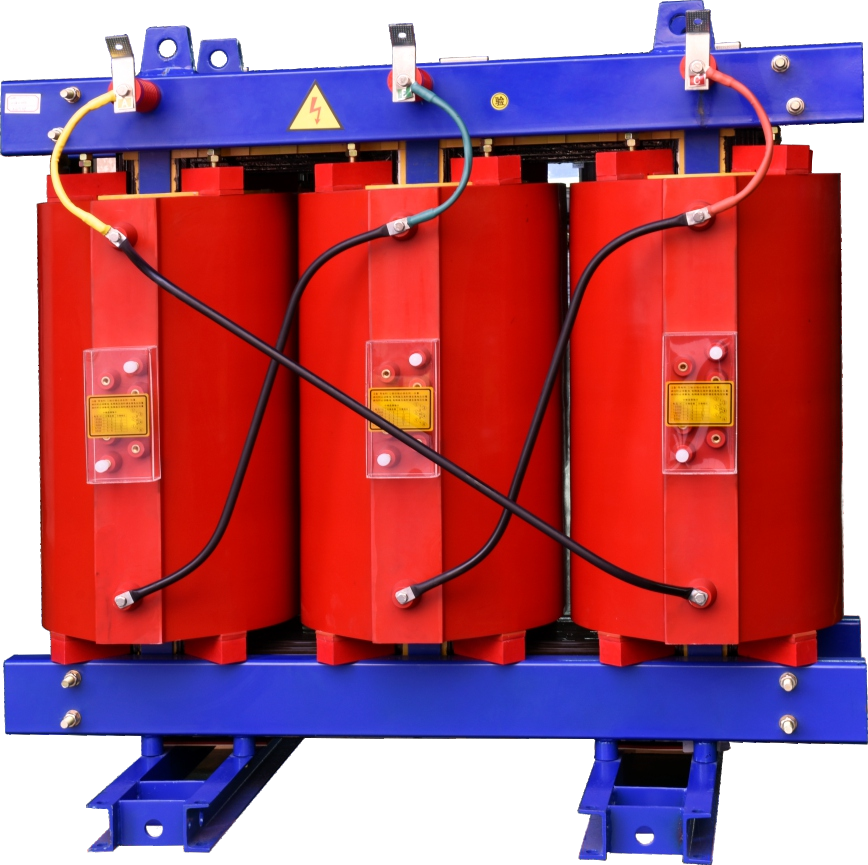

35kV Dry Type Transformer

35kV Dry Type Transformer is safe, flame retardant, fire resistant and non-polluting, and can be installed directly in the load center. No maintenance, easy installation. It has good moisture-proof performance and can be put into operation without pre-drying after shutdown. It has low loss, low local discharge power, and low noise, and can be operated 120 % rated load under forced air-cooling conditions. It is equipped with a perfect temperature protection control system to provide reliable guarantee for the safe operation of the Transformer. The reliability index of this product has reached the advanced level in China.

TEL:16515111777

Product details

35kV Dry Type Transformer is safe, flame retardant, fire resistant and non-polluting, and can be installed directly in the load center. No maintenance, easy installation. It has good moisture-proof performance and can be put into operation without pre-drying after shutdown. It has low loss, low local discharge power, and low noise, and can be operated 120 % rated load under forced air-cooling conditions. It is equipped with a perfect temperature protection control system to provide reliable guarantee for the safe operation of the Transformer. The reliability index of this product has reached the advanced level in China.

◆The coil is wound with copper wire or foil, reinforced with glass fiber, epoxy resin is not filled with vacuum drying and dehumidifying. The epoxy resin can be integrally casted under the condition of vacuum drying, degassing and dehumidification without filler, high mechanical strength, short circuit resistance and strong impact resistance;

◆The first and end of the high-pressure winding and the middle splice are pre-buried with copper embedded parts, and the steel is good, easy to adjust the file, and the beauty is neat;

◆The iron core is made of high-quality grain orientation cold rolled Silicon steel sheets, 45 degrees full inclined multi-step joints. The surface is covered with a resin insulating coating, which is resistant to moisture, rust and noise.

◆ The elastic parts are clamped between the iron core, clamp and coil, so that the coil is in a stable compression state to reduce noise;

◆The Transformer is designed according to self-cooling, and a longitudinal ventilation channel is reserved inside the wall of the high(low) pressure coil tube for overall pouring. It can be equipped with a forced air-cooling device (cooling fan). After adopting a forced air-cooling device, the output capacity can be increased by 50 %;

◆Equipped with a thermostat, a platinum resistor (Pt100) is placed in the pre-embedded hole at the top of the low voltage coil. In order to monitor the temperature rise of the transformer winding, automatically stop the cooling fan and equipped with fault alarm, overtemperature alarm and overtemperature jump function, provide reliable overload protection device for the dry Transformer, thus improving the safety of the dry Transformer operation.